Six Sigma – how to optimise results

We use Six Sigma to enable your organisation to make immediate and long-lasting improvements to all your business processes: from business decision making, to machinery settings.

Our training courses are accredited by The Institute of Six Sigma Professionals, and are designed to ensure delegates can immediately apply the tools they have learnt – making instant savings in your organisation.

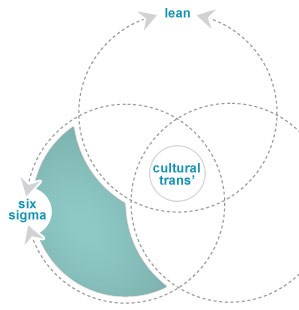

Six Sigma is a data driven business improvement methodology built around robust change management principles and and statistical rigour. ‘Lean’ looks to change the process to ensure it is ‘fit for purpose’, while ‘Six Sigma’ looks to optimise the process and is about going after the last 5% improvement – not the first 5%. In fact, Six Sigma defines ‘perfection’ and strives to eliminate any variation or deviation from the process target.

The Six Sigma methodology consists of five interconnected phases, each with specific deliverables, known as DMAIC.

- Define – Define the project, the problem and the process.

- Measure – Establish performance standards and determine process capability.

- Analyse – Investigate data to prove suspected key sources of variation

- Improve – Develop, validate and implement solutions

- Control – Implement controls and monitor process stability

In addition to this DMAIC methodology, Six Sigma has an enormous statistical toolkit for measuring, analysing, simulating and improving processes. The massive processing power of computers mean that problems we couldn’t solve five years ago can now be solved in minutes. Six Sigma enables us to model, simulate and optimise linear processes, non linear processes and, to a degree, predict the unknown through statistical modelling.

Six Sigma ‘Green Belts’ and ‘Black Belts’ are people who have undergone rigorous training in the Six Sigma tools, and have taken part in, lead or directed either small or large Six Sigma improvement projects in their company. Typically, it is expected that a Black Belt Six Sigma project would save a company £100k, while a Green Belt Six Sigma project would save a company £20k. For more information, see Six Sigma Training.

Six Sigma was initiated in 1981 in Motorola, where they saved $15 billion in 15 years. Six Sigma has since been successfully implemented in a wide range of industries, from its origins in manufacturing to Housing Associations and Public Sector. See Six Sigma Case Studies, for specific examples.

Lean and Six Sigma have been successfully combined into a powerful process improvement approach. In all cases, it is essential to fully understand the tools, and have the maturity and experience to identify the most appropriate approach. Lighthouse Consultants will always support clients in developing their own in-house skills for both Lean and Six Sigma, and provide ongoing mentoring support for Black Belt Six Sigma delegates, as well as helping with strategic Six Sigma deployment. See Six Sigma Consultancy.

All delegates on Lighthouse Consultants’ Six Sigma courses will be encouraged to join the Institute of Six Sigma Professionals, and the Black Belt training course meets the requirements of the Institute’s criteria for ‘Professional’ membership.